Spiral Wound Gasket Selector

Solid outer ring spiral wound gaskets consist of a metal guide ring and sealing element. The external ring accurately centers gasket on flange face: provides additional radial strength to prevent gasket blowout and acts as a compression stop. This profile is normally used in raised and flat faced flanged. The outer ring is often made of carbon steel (painted or zinc plated to prevent corrosion) but can be made of alloys for higher temperature and more severe medium applications.

Sprial Wound Styles

911/911T

This is simplest style of spiral wound gasket, consisting of a circular winding without centering or inner rings. Spiral wound gaskets Style 911 are mainly used in tongue and groove or male and female. They are also used in equipment with space and weight limitations.

Style 911-T has better sealability than a coventional heat exchanger double-jacketed gasket. However, a specially machined groove with an appropiate compression stop in needed for 911-T.

911M

A style 911-M gasket is a sealing winding with an inner ring. The purpose of this ring is to fill out the space between the flanges, avoiding turbulence in the flow of the fluid or as a protection against corrosion or erosion. It is also used as a compression limit when the seating stress is greater than 30,000 psi (210 MPa).

Gaskets with PTFE filler have a tendency to inward buckle thus the use of an inner ring is recommended if the gasket is to be installed with a non-confined inside diameter.

913

The construction of this gasket is circular metal winding with an outer guide ring. The sealing element is made of the specified metal and soft sealing material. The standard pipe size gaskets are made to ASME B16.20 (see also style 913M). These gaskets are used in a very wide variety of applications.

913M

The 913M is the standard spiral wound gasket with an inner ring. The purpose of this ring is to fill out the space between the flanges, avoiding turbulence in the flow of the fluid or as protection against corrosion or erosion. It is also used as a compression limit. Gaskets with PTFE filler have a tendency to inward buckle thus the use of an inner ring is required by ASME B16.20. Inner rings are also required with ASME standard spiral wound gaskets with flexible graphite fillers unless the purchaser specifies otherwise and some sizes and pressure class require inner rings regardless of filler material.

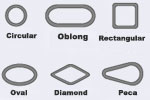

914

Style 914 spiral wound gaskets are windings in non-circular forms like oval, rectangular and square with rounded corners, diamonds, oblong or pear shaped. Style 914 gaskets are used in boiler handholes and manholes, equipment, engine head-gaskets and exhaust systems. Inner rings should also be used for many of these applications.

Materials

The color painted on the outer rim of the Spiral Wound Gasket quickly identifies the materials used to produce the gasket. The following table explains what each color means.

| WINDING | |

|---|---|

| Material | O.D. Ring Color |

| 304 Stainless Steel | Yellow |

| 316L Stainless Steel | Green |

| 317L Stainless Steel | Maroon |

| 321 Stainless Steel | Turquoise |

| 347 Stainless Steel | Blue |

| Nickel | Red |

| Titanium | Purple |

| Alloy 20 | Black |

| Inconel®600 | Gold |

| HASTELLOY® B | Brown |

| HASTELLOY® C | Beige |

| INCOLOY® 800 | White |

| FILLER | |

|---|---|

| Material | Strip Color |

| PTFE | White |

| Flexible Graphite | Gray |

| Ceramic | Lt. Green |

Our Currently Available Spiral Wound Gasket Options

Spiral Wound Gaskets (No Inner Ring)

276 Hastelloy C Spiral Wound Gasket - Flexible Graphite Filler - No Inner Ring - Beige Band with Gray Stripes

276 Hastelloy C Spiral Wound Gasket - Flexible Graphite Filler - No Inner Ring - Beige Band with Gray Stripes. The construction of this gasket is circular metal winding with an outer guide ring. The sealing element is made of the specified metal and soft sealing material. The standard pipe size gaskets are made to ASME B16.20 (see also style 913M). These gaskets are used in a very wide variety of applications.

304 Stainless Steel - Flexible Graphite Filler - No Inner Ring - Yellow Band with Grey Stripes

304 Stainless Steel - Flexible Graphite Filler - No Inner Ring - Yellow Band with Grey Stripes. The construction of this gasket is circular metal winding with an outer guide ring. The sealing element is made of the specified metal and soft sealing material. The standard pipe size gaskets are made to ASME B16.20 (see also style 913M). These gaskets are used in a very wide variety of applications.

316L Stainless Steel - Flexible Graphite Filler - No Inner Ring - Green Band with Grey Stripes

316L Stainless Steel - Flexible Graphite Filler - No Inner Ring - Green Band with Grey Stripes. The construction of this gasket is circular metal winding with an outer guide ring. The sealing element is made of the specified metal and soft sealing material. The standard pipe size gaskets are made to ASME B16.20 (see also style 913M). These gaskets are used in a very wide variety of applications.

321 Stainless Steel - Flexible Graphite Filler - No Inner Ring - Turquoise Band with Grey Stripes

321 Stainless Steel - Flexible Graphite Filler - No Inner Ring - Turquoise Band with Grey Stripes. The construction of this gasket is circular metal winding with an outer guide ring. The sealing element is made of the specified metal and soft sealing material. The standard pipe size gaskets are made to ASME B16.20 (see also style 913M). These gaskets are used in a very wide variety of applications.

347 Stainless Steel - Flexible Graphite Filler - No Inner Ring - Blue Band with Grey Stripes

347 Stainless Steel - Flexible Graphite Filler - No Inner Ring - Blue Band with Grey Stripes. The construction of this gasket is circular metal winding with an outer guide ring. The sealing element is made of the specified metal and soft sealing material. The standard pipe size gaskets are made to ASME B16.20 (see also style 913M). These gaskets are used in a very wide variety of applications.

600 Inconel® - Flexible Graphite Filler - No Inner Ring - Gold Band with Grey Stripes

600 Inconel® - Flexible Graphite Filler - No Inner Ring - Gold Band with Grey Stripes. The construction of this gasket is circular metal winding with an outer guide ring. The sealing element is made of the specified metal and soft sealing material. The standard pipe size gaskets are made to ASME B16.20 (see also style 913M). These gaskets are used in a very wide variety of applications.

Spiral Wound Gaskets with Inner Ring

304 Stainless Steel - Flexible Graphite Filler - 304SS Inner Ring - Yellow Band with Grey Stripes

304 Stainless Steel - Flexible Graphite Filler - 304SS Inner Ring - Yellow Band with Grey Stripes. The purpose of the inner ring is to fill out the space between the flanges, avoiding turbulence in the flow of the fluid or as protection against corrosion or erosion. It is also used as a compression limit. Gaskets with PTFE filler have a tendency to inward buckle thus the use of an inner ring is required by ASME B16.20. Inner rings are also required with ASME standard spiral wound gaskets with flexible graphite fillers unless the purchaser specifies otherwise and some sizes and pressure class require inner rings regardless of filler material.

316L Stainless Steel - Flexible Graphite Filler - 316LSS Inner Ring - Green Band with Grey Stripes

316L Stainless Steel - Flexible Graphite Filler - 316LSS Inner Ring - Green Band with Grey Stripes. The purpose of the inner ring is to fill out the space between the flanges, avoiding turbulence in the flow of the fluid or as protection against corrosion or erosion. It is also used as a compression limit. Gaskets with PTFE filler have a tendency to inward buckle thus the use of an inner ring is required by ASME B16.20. Inner rings are also required with ASME standard spiral wound gaskets with flexible graphite fillers unless the purchaser specifies otherwise and some sizes and pressure class require inner rings regardless of filler material.

321 Stainless Steel - Flexible Graphite Filler - 321SS Inner Ring - Turquoise Band with Grey Stripes

321 Stainless Steel - Flexible Graphite Filler - 321SS Inner Ring - Turquoise Band with Grey Stripes. The purpose of the inner ring is to fill out the space between the flanges, avoiding turbulence in the flow of the fluid or as protection against corrosion or erosion. It is also used as a compression limit. Gaskets with PTFE filler have a tendency to inward buckle thus the use of an inner ring is required by ASME B16.20. Inner rings are also required with ASME standard spiral wound gaskets with flexible graphite fillers unless the purchaser specifies otherwise and some sizes and pressure class require inner rings regardless of filler material.