Public Works

Waste Management and Garbage Collection

This garbage truck is fully greased with Interflon LS2, which boasts exceptional, long-lasting wear resisting properties and prevents loss of lubricating protection, even from water.

These turnbuckles are notorious for squeaks and poor movement with other greases after just a few routes. After greasing with Interflon LS2, it remains smooth & silent after over 1 year of the truck going out daily.

These hydraulic pistons are used to compress the garbage after collection. After applying Interflon to these, they compress without any friction or snags.

Interflon LS2 Grease was applied to this can tipper at the rear of the garbage truck, considerably reducing wear and friction.

Interflon HT1200 Anti-Seize has been applied to all threaded connections on this MUA garbage truck.

Water Treatment

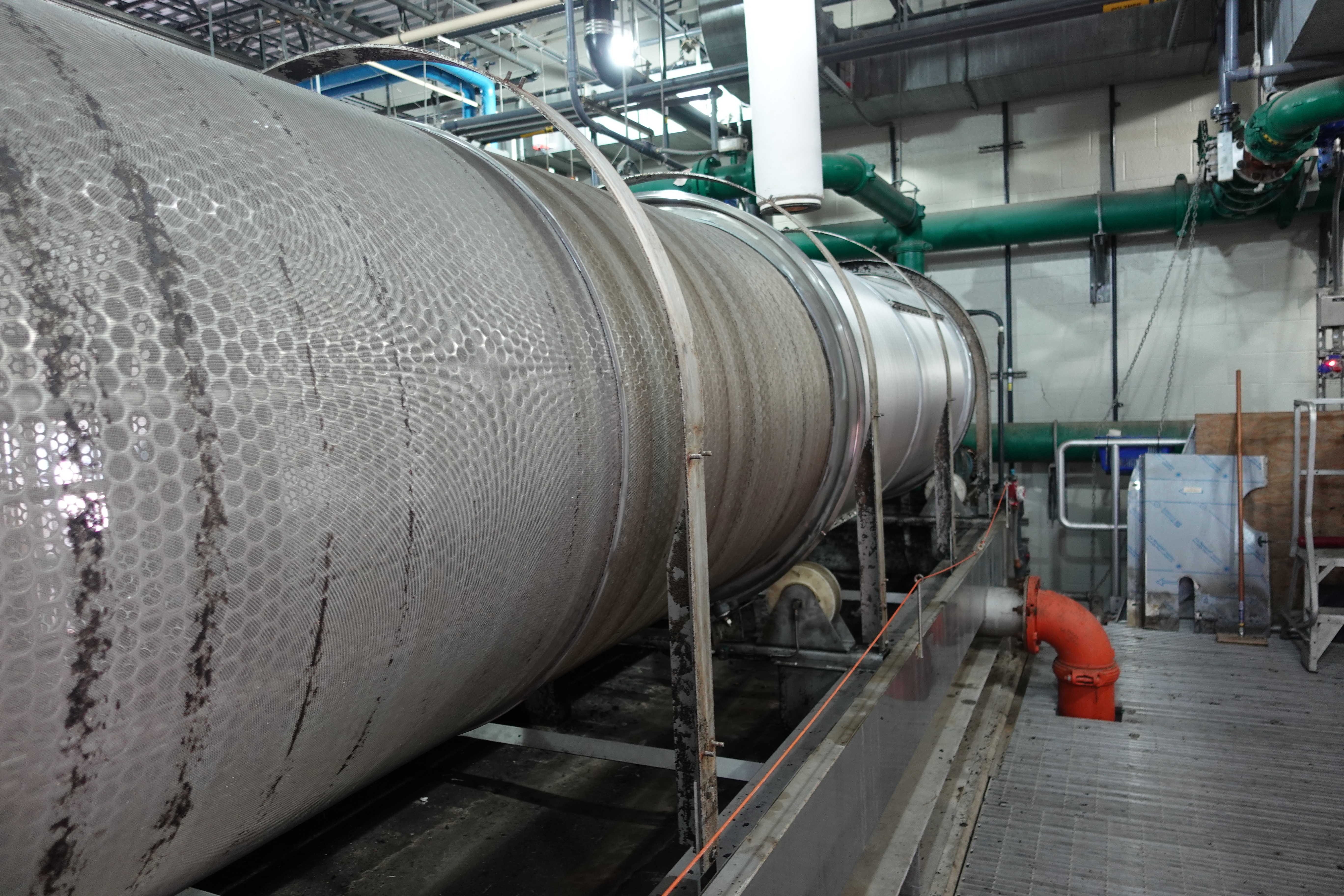

These Sludge Dewatering Rotating Drums require grease and oil to maintain a smooth rotation. Interflon reduces the amount of grease needed and lessens the greasing intervals. It also reduces wear and prolongs life of equipment.

This is one of the grease joints for the rotating drum. This is before Interflon is put onto it. Interflon will not produce this much dirt, as it reduces and reflects grime and dirt when applied to any surface.

Interflon LS2 Grease with MicPol technology reduces friction and eliminates wear on the moving components in sludge and effluent tanks, and Interflon MP2/3 Grease extends the operating life and maintenance intervals of electric motors in water treatment plants.

Within any industry for Public Works, these Interflon products are primarily used:

HT1200 Anti-Seize

Fin Super

Metal Clean F

EM30+ Degreaser

LS2 and MP2/3 Grease