Flange Basics

ASME standards describe several designs, but the most common are the raised face and the flat face. The difference between them is that the raised face flange has a raised region surrounding the pipe bore. The bolt holes are outside of this. The flat face flange has no such step. For either raised face or flat face flanges there are two available types of gaskets. Ring Gaskets are a continuous ring and full-face gaskets include bolt holes.

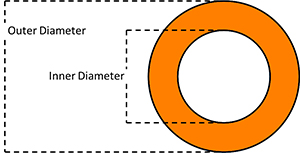

The Ring-Type Gasket

This is positioned inside of the flange bolts and around the pipe bore. In a raised face design it sits on that surface. This design requires less material and less cutting. They can be installed without completely dissembling the joint, (making it a “drop in” gasket.) The downside is that it is harder to clamp in position.

When specifying a ring type gasket only three measurements are needed: Inner Diameter (ID) (which corresponds to the pipe bore,) Outer Diameter (OD) (which is the same as the OD of the raised face) gasket thickness, and pressure tolerance of the gasket needed, they come in tolerances of 150 psi or 300 psi.

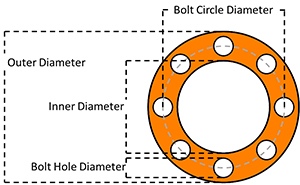

The Full-Face Gasket

Like the ring-type gasket, this seals on raised flange faces, but has an Outer Diameter (OD) the same as the flange. That means it needs holes for the securing bolts to pass through, and these help locate it on the flange, making alignment easier. Extending out to the flange OD has the added benefit of filling the gap between bolting surfaces, which stops dirt from getting in. However, the joint must be completely disassembled for installation.

When specifying a ring type gasket only three measurements are needed: Inner Diameter (ID) (which corresponds to the pipe bore,) Outer Diameter (OD) (which is the same as the OD of the raised face) gasket thickness, the number of bolt holes, bolt circle diameter and pressure tolerance of the gasket needed, they come in tolerances of 150 psi or 300 psi.

Here is a Helpful Table of Standard Sizes of Flange Gaskets

| Pipe Size | Flange ASA Rating in lbs. | Ring Gasket | Full face Gasket | No. of Bolt Holes | Bolt Hole Diameter | Bolt Circle Diameter | ||

| Old Stanard | New Standard | Old Stanard | New Standard | |||||

| 3/4" | 150 | 3/4" x 2-1/4" | 1-1/16" x 2-1/4" | 3/4" x 3-7/8" | 1-1/16" x 3-7/8" | 4 | 5/8" | 2-3/4" |

| 300 | 3/4" x 2-5/8" | 1-1/16" x 2-5/8" | 3/4" x 4-5/8" | 1-1/16" x 4-5/8" | 4 | 3/4" | 3-1/4" | |

| 1" | 150 | 1" x 2-5/8" | 1-5/16" x 2-5/8" | 1" x 4-1/4" | 1-5/16" x 4-1/4" | 4 | 5/8" | 3-1/8" |

| 300 | 1" x 2-7/8" | 1-5/16" x 2-7/8" | 1" x 4-7/8" | 1-5/16" x 4-7/8" | 4 | 3/4" | 3-1/2" | |

| 1-1/4" | 150 | 1-1/4" x 3" | 1-21/32" x 3" | 1-1/4" x 4-5/8" | 1-21/32" x 4-5/8" | 4 | 5/8" | 3-1/2" |

| 300 | 1-1/4" x 3-1/4" | 1-21/32" x 3-1/4" | 1-1/4" x 5-1/4" | 1-21/32" x 5-1/4" | 4 | 3/4" | 3-7/8" | |

| 1-1/2" | 150 | 1-1/2" x 3-3/8" | 1-29/32" x 3-3/8" | 1-1/2" x 5" | 1-29/32" x 5" | 4 | 5/8" | 3-7/8" |

| 300 | 1-1/2" x 3-3/4" | 1-29/32" x 3-3/4" | 1-1/2" x 6-1/2" | 1-29/32" x 6-1/8" | 4 | 7/8" | 4-1/2" | |

| 2" | 150 | 2" x 4-1/8" | 2-3/8" x 4-1/8" | 2" x 6" | 2-3/8" x 6" | 4 | 3/4" | 4-3/4" |

| 300 | 2" x 4-3/8" | 2-3/8" x 4-3/8" | 2" x 6-1/2" | 2-3/8" x 6-1/2" | 8 | 3/4" | 5" | |

| 2-1/2" | 150 | 2-1/2" x 4-7/8" | 2-7/8" x 4-7/8" | 2-1/2" x 7" | 2-7/8" x 7" | 4 | 3/4" | 5-1/2" |

| 300 | 2-1/2" x 5-1/8" | 2-7/8" x 5-1/8" | 2-1/2" x 7-1/2" | 2-7/8" x 7-1/2" | 8 | 7/8" | 5-7/8" | |

| 3" | 150 | 3" x 5-3/8" | 3-1/2" x 5-3/8" | 3" x 7-1/2" | 3-1/2" x 7/1/2" | 4 | 3/4" | 6" |

| 300 | 3" x 5-7/8" | 3-1/2" x 5-7/8" | 3" x 8-1/4" | 3-1/2" x 8-1/4" | 8 | 7/8" | 6-5/8" | |

| 4" | 150 | 4" x 6-7/8" | 4-1/2" x 6-7/8" | 4" x 9" | 4-1/2" x 9" | 8 | 3/4" | 7-1/2" |

| 300 | 4" x 7-1/8" | 4-1/2" x 7-1/8" | 4" x 10" | 4-1/2" x 10" | 8 | 7/8" | 7-7/8" | |

| 5" | 150 | 5" x 7-3/4" | 5-9/16" x 7-3/4" | 5" x 10" | 5-9/16" x 10" | 8 | 7/8" | 8-1/2" |

| 300 | 5" x 8-1/2" | 5-9/16" x 8-1/2" | 5" x 11" | 5-9/16" x 11" | 8 | 7/8" | 9-1/4" | |

| 6" | 150 | 6" x 8-3/4" | 6-5/8" x 8-3/4" | 6" x 11" | 6-5/8" x 11" | 8 | 7/8" | 9-1/2" |

| 300 | 6" x 9-7/8" | 6-5/8" x 9-7/8" | 6" x 12-1/2" | 6-5/8" x 12-1/2" | 12 | 7/8" | 10-5/8" | |

| 8" | 150 | 8" x 11" | 8-5/8" x 11" | 8" x 13-1/2" | 8-5/8" x 13-1/2" | 8 | 7/8" | 11-3/4" |

| 300 | 8" x 12-1/8" | 8-5/8" x 12-1/8" | 8" x 15" | 8-5/8" x 15" | 12 | 1" | 13" | |

| 10" | 150 | 10" x 13-3/8" | 10-3/4" x 13-3/8" | 10" x 16" | 10-3/4" x 16" | 12 | 1" | 14-1/4" |

| 300 | 10" x 14-1/4" | 10-3/4" x 14-1/4" | 10" x 17-1/2" | 10-3/4" x 17-1/2" | 16 | 1-1/8" | 15-1/4" | |

| 12" | 150 | 12" x 16-1/8" | 12-3/4" x 16-1/8" | 12" x 19" | 12-3/4" x 19" | 12 | 1" | 17" |

| 300 | 12" x 16-5/8" | 12-3/4" x 16-5/8" | 12" x 20-1/2" | 12-3/4" x 20-1/2" | 16 | 1-1/4" | 17-3/4" | |

| 14" | 150 | 14" X 17-3/4" | 14" x 17-3/4" | 14" x 21" | 14" x 21" | 12 | 1-1/8" | 18-3/4" |

| 300 | 14" X 19-1/8" | 14" x 19-1/8" | 14" x 23" | 14" x 23" | 20 | 1-1/4" | 20-1/4" | |

| 16" | 150 | 16" X 20-1/4" | 16" x 20-1/4" | 16" x 23-1/2" | 16" x 23-1/2" | 16 | 1-1/8" | 21-1/4" |

| 300 | 16" X 21-1/4" | 16" x 21-1/4" | 16" x 25-1/2" | 16" x 25-1/2" | 20 | 1-3/8" | 22-1/2" | |

| 18" | 150 | 18" X 21-5/8" | 18" x 21-5/8" | 18" x 25" | 18" x 25" | 16 | 1-1/4" | 23-3/4" |

| 300 | 18" X 23-1/2" | 18" x 23-1/2" | 18" x 28" | 18" x 28" | 24 | 1-3/8" | 24-3/4" | |

| 20" | 150 | 20" X 23-7/8" | 20" x 23-7/8" | 20" x 27-1/2" | 20" x 27-1/2" | 20 | 1-1/4" | 25 |

| 300 | 20" X 25-5/8" | 20" x 25-5/8" | 20" x 30-1/2" | 20" x 30-1/2" | 24 | 1-3/8" | 27" | |

| 24" | 150 | 24" X 28-1/4" | 24" x 28-1/4" | 24" x 32" | 24" x 32" | 20 | 1-3/8" | 29-1/2" |

| 300 | 24" X 30-3/8" | 24" x 30-3/8" | 24" x 36" | 24" x 36" | 24 | 1-5/8" | 32" | |

| 26" | 150 | 26" x 30-1/2" | 26" x 30-1/2" | 26" x 34-1/4" | 26" x 34-1/4" | |||

| 300 | 26" x 32-7/8" | 26" x 32-7/8" | ||||||

| 28" | 150 | 28" x 32-3/4" | 28" x 32-3/4" | 28" x 36-1/2" | 28" x 36-1/2" | |||

| 300 | 28" x 35-3/8" | 28" x 35-3/8" | ||||||

| 30" | 150 | 30" x 34-5/8" | 30" x 34-5/8" | 30" x 38-3/4" | 30" x 38-3/4" | |||

| 300 | 30" x 37-1/2" | 30" x 37-1/2" | ||||||

Elastomers

Elastomer is a term derived from elastic polymer, which is often used interchangeably with the term rubber. Each of the monomers which link to form the polymer are usually made of carbon, hydrogen, oxygen and/or silicon. Elastomers are usually thermosets requiring a curing process involving heat and the addition of sulfur or other equivalent curatives.

SBR (Styrene-Butadiene) is a synthetic rubber that has excellent abrasion resistance and resistance to weak organic acids, alcohols, moderate chemicals and ketones. It is not good in ozone, strong acids, fats, oils, greases and most hydrocarbons. Its temperature range would be from approximately -65°F to 250°F (-54°C to 121°C).

CR-Chloroprene (Neoprene) is a synthetic rubber that is suitable for use against moderate acids, alkalies and salt solutions. It has good resistance to commercial oils and fuels. It is very poor against strong oxidizing acids, aromatic and chlorinated hydrocarbons. Its temperature range would be from approximately -60°F to 250°F (-51°C to 121°C).

Buna-N/Rubber (Nitrile, NBR) is a synthetic rubber that has good resistance to oils and solvents, aromatic and aliphatic hydrocarbons, petroleum oils and gasoline over a wide range of temperature. It also has good resistance to caustics and salts but only fair acid resistance. It is poor in strong oxidizing agents, chlorinated hydrocarbons, ketones and esters. It is suitable over a temperature range of approximately -60°F to 250°F (-51°C to 121°C).

EPDM (Ethylene Propylene) This synthetic material has good resistance to strong acids, alkalies, salts and chlorine solutions. It is not suitable for use in oils, solvents or aromatic hydrocarbons. Its temperature range would be between -70°F to 350°F (-57°C to 177°C).

Fluorocarbon (Viton®) Fluorocarbon elastomer has good resistance to oils, fuel, chlorinated solvents, aliphatic and aromatic hydrocarbons and strong acids. It is not suitable for use against amines, esters, ketones or steam. Its normal temperature range would be between -15°F to 450°F (-26°C to 232°C).

Chlorosulfonated Polyethylene (Hypalon®) Chlorosulfonated Polyethylene has acid, alkali and salt resistance. It resists weathering, sunlight, ozone, oils and commercial fuels such as diesel and kerosene. It is not good in aromatics or chlorinated hydrocarbons and has poor resistance against chromic acid and nitric acid. Its normal temperature range would be between -50°F and 275°F (-46°C and 135°C).

Natural Rubber is resistant to mild acids and alkalis, salts and chlorine solutions. It has poor resistance to oils and solvents and is not recommended for use with ozone. Its temperature range is very limited and is suitable only for use from -70°F to 200°F (-57°C to 93°C).

Silicone rubbers have good resistance to hot air. They are unaffected by sunlight and ozone. They are not, however, suitable for use against steam, aliphatic and aromatic hydrocarbons. The temperature range would be between -65°F to 500°F (-54°C to 260°C).

Vegetable Fiber Sheet Vegetable fiber sheet is a tough pliable gasket material manufactured by paper making techniques utilizing plant fibers and a glue-glycerine impregnation. It is widely used for sealing petroleum products, gases and a wide variety of solvents. Its maximum temperature limit is 250°F (121°C). If a more compressible material is required, a combination cork-fiber sheet is available. The cork-fiber sheet has the same maximum temperature limitation as the vegetable fiber sheet.

Installation

Full-face and ring gaskets will do an equally good job of sealing the joint. The difference really boils down to installation preferences and priorities. You will get maximum performance from our gasket materials when you use our Gasket Installation Procedure.

[1] Clean and inspect the flanges, surface or parts that require gasket.

[2] Clean or replace your bolts, nuts & washers.

[3] Lubricate the bolt's, thread, nuts, washers and the underside of the head with Graphite based compound.

[4] Flat washers are recommended to assure even distribution of the bolting force.

[5] Ensure lubricant doesn’t contaminate gasket.

[6] Carefully insert the gasket between the mating surfaces.

[7] The use of a torque wrench is highly recommended. This assures a longer life and leak free performance. Whether an automotive head gasket or a flange gasket, it should be torqued.

[8] Make four even increment passes in a 12-6-3-9 o'clock pattern sequence.

[9] The appropriate stress on the gasket material you use is key to its success which varies depending material chosen.

Our Currently Available Full Face and Ring Gasket Options

Full Face Gaskets

1100 Style Carbon and Graphite with Nitrile Binder Full Face Gaskets

Resistant to a wide range of temperatures including Maximum Service of 842 degrees F (450 degrees C). Pressure Rating for Continuous Service is 1015 psi (70 bar), and a Maximum Service of 1885 psi (130 bar). Compressibility - ASTM F36 5 - 15%. Recovery - ASTM F36 min 50%. Sur-Seal, Inc. of NJ Style 1100 made of Carbon and Graphite with Nitrile Binder has proven their long-term reliability under extreme operating conditions over the course of many years.

NSF-61 Certified EPDM Full Face Gaskets

NSF-61 Certified EPDM Ring Gaskets are used for potable water systems and help reduse lead leaching and other water contaminators. SPECIFICATION ASTM D2000; Hardness Shore A 75 +/- 5, ASTM D1330 Grade 1 & 2, POLYMER: Ethylene-Propylene (EPDM); ASTM D412 TENSILE (PSI): 1500 min.; ULTIMATE ELONGATION(%) 250 min. ASTM Grade.

1501 Style Expanded PTFE Full Face Gaskets

Expanded PTFE is highly conformable to rough or irregular sealing surfaces, and compresses into an extremely tough gasket that creates a tight, long- lasting seal. It is suitable for service at temperatures up to 500 Degrees Fahrenheit and pressure vacuum up to 2900psi (200bar).

7000 Style Flexible Graphite Full Face Gaskets

Resistant to a wide range of temperatures including a minimum of [-400 Degrees F (-240 Degrees C), and maximum of +850 Degrees F (+454 Degrees C), (in atmosphere).] [+1200 Degrees F (+650 Degrees C) to +5432 Degrees F (+3000 Degrees C) in continuous reduction or inert media.] Seals easily under moderate bolt loads and reduces gasket damage in handling and installation.

7000T Style Flexible Graphite Full Face Gaskets

7000T Style Gaskets are made of expanded flexible graphite have proven their long-term reliability under extreme operating conditions over the course of many years. While maintaining an effective seal, 7000T Style Gaskets exhibit virtually no creep relaxation. As a result, the need for periodic bolt tightening is greatly reduced.

NSF-61 Certified Full Face Teadit NA1082SAN Gaskets

Teadit style NA1082SAN is specifically formulated to pass criteria established in NSF-61 for sealing materials, as well as providing excellent resistance to conductivity. Compressed Fiber Sheet technology provides mechanical and service characteristics unmatched by standard elastomeric grades.

7237 Style Red Rubber Full Face Gaskets

7237 Style Red Rubber SBR conforms easily to uneven flange surfaces, has good abrasion resistance, excellent impact strength, very good resilience and a high tensile strength.

7175 Style Silicone Full Face Gaskets

Silicone is a very popular flange gasket for hot or cold water. Because silicone is odorless and tasteless, it is ideal for certain surgical and food processing applications. Silicone rubber sheet has poor resistance to oils, fuels, and hydrocarbons. Fair performance when exposed to acids, alkalis and solvents.

7530 Style Virgin PTFE Full Face Gaskets

Virgin PTFE sheet can handle virtually all chemicals in the 0-14 pH range with the exception of molten alkali metals and elemental fluorine. It is suitable for service at temperatures from the cryogenic range up to 500 Degrees F. Sur-Seal, Inc. 7530 is particularly recommended for applications in the food and beverage industry where high purity materials are required.

7106 Style Neoprene Full Face Gaskets

7106 Style Neoprene 60 Durometer rubber is a very good general service gasket material that has numerous applications in the process industries and in the water and wastewater industry. Temperature range -20 F to 190 F.

7157 EPDM 60 Durometer Full Face Gaskets

The resistance to polar substances and steam are also excellent. It has great electrical insulating properties. It has good resistance to ketones, ordinary diluted acids, and alkalis. 7157 Style EPDM has excellent resistance to oxygen, acids, and aging; outstanding color stability, Odor-free characteristics, high heat resistance and dielectric qualities. All of this makes it ideal for outdoor applications and as a general purpose gasket material for air, hot and cold water, and saturated steam.

Ring Gaskets

1100 Style Carbon and Graphite with Nitrile Binder Ring Gaskets

Resistant to a wide range of temperatures including Maximum Service of 842 degrees F (450 degrees C). Pressure Rating for Continuous Service is 1015 psi (70 bar), and a Maximum Service of 1885 psi (130 bar). Compressibility - ASTM F36 5 - 15%. Recovery - ASTM F36 min 50%. Sur-Seal, Inc. of NJ Style 1100 made of Carbon and Graphite with Nitrile Binder has proven their long-term reliability under extreme operating conditions over the course of many years.

NSF-61 Certified EPDM Ring Gaskets

NSF-61 Certified EPDM Ring Gaskets are used for potable water systems and help reduse lead leaching and other water contaminators. SPECIFICATION ASTM D2000; Hardness Shore A 75 +/- 5, ASTM D1330 Grade 1 & 2, POLYMER: Ethylene-Propylene (EPDM); ASTM D412 TENSILE (PSI): 1500 min.; ULTIMATE ELONGATION(%) 250 min. ASTM Grade.

1501 Style Expanded PTFE Ring Gaskets

Expanded PTFE is highly conformable to rough or irregular sealing surfaces, and compresses into an extremely tough gasket that creates a tight, long- lasting seal. It is suitable for service at temperatures up to 500 Degrees Fahrenheit and pressure vacuum up to 2900psi (200bar).

7000 Style Flexible Graphite Ring Gaskets

Resistant to a wide range of temperatures including a minimum of [-400 Degrees F (-240 Degrees C), and maximum of +850 Degrees F (+454 Degrees C), (in atmosphere).] [+1200 Degrees F (+650 Degrees C) to +5432 Degrees F (+3000 Degrees C) in continuous reduction or inert media.] Seals easily under moderate bolt loads and reduces gasket damage in handling and installation.

7000T Style Flexible Graphite Ring Gaskets

7000T Style Gaskets are made of expanded flexible graphite have proven their long-term reliability under extreme operating conditions over the course of many years. While maintaining an effective seal, 7000T Style Gaskets exhibit virtually no creep relaxation. As a result, the need for periodic bolt tightening is greatly reduced.

NSF-61 Certified Teadit NA1082SAN Ring Gaskets

Teadit style NA1082SAN is specifically formulated to pass criteria established in NSF-61 for sealing materials, as well as providing excellent resistance to conductivity. Compressed Fiber Sheet technology provides mechanical and service characteristics unmatched by standard elastomeric grades.

7237 Style Red Rubber Ring Gaskets

7237 Style Red Rubber SBR conforms easily to uneven flange surfaces, has good abrasion resistance, excellent impact strength, very good resilience and a high tensile strength.

7175 Style Silicone Ring Gaskets

Silicone is a very popular flange gasket for hot or cold water. Because silicone is odorless and tasteless, it is ideal for certain surgical and food processing applications. Silicone rubber sheet has poor resistance to oils, fuels, and hydrocarbons. Fair performance when exposed to acids, alkalis and solvents.

7530 Style Virgin PTFE Ring Gaskets

Virgin PTFE sheet can handle virtually all chemicals in the 0-14 pH range with the exception of molten alkali metals and elemental fluorine. It is suitable for service at temperatures from the cryogenic range up to 500 Degrees F. Sur-Seal, Inc. 7530 is particularly recommended for applications in the food and beverage industry where high purity materials are required.

7106 Style Neoprene Ring Gaskets

7106 Style Neoprene 60 Durometer rubber is a very good general service gasket material that has numerous applications in the process industries and in the water and wastewater industry. Temperature range -20 F to 190 F.

7157 EPDM 60 Durometer Ring Gaskets

The resistance to polar substances and steam are also excellent. It has great electrical insulating properties. It has good resistance to ketones, ordinary diluted acids, and alkalis. 7157 Style EPDM has excellent resistance to oxygen, acids, and aging; outstanding color stability, Odor-free characteristics, high heat resistance and dielectric qualities. All of this makes it ideal for outdoor applications and as a general purpose gasket material for air, hot and cold water, and saturated steam.