Interflon

What makes Interflon Different?

MicPol®

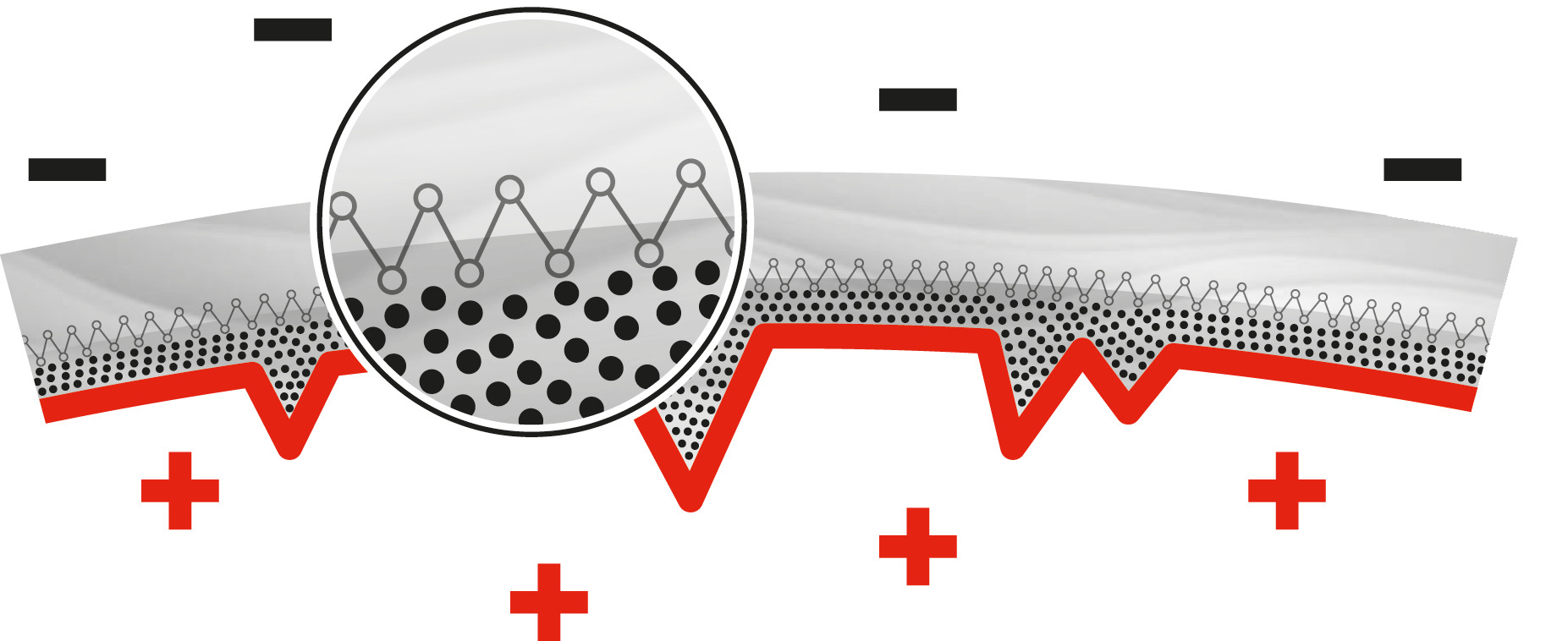

MicPol® stands for Micronization and Polarization. It is the signature technology that makes Interflon products far exceed any of its competitors in efficiency.

Micronization: through the development process, lubrication particulates are reduced to around 0.05 microns in size. This allows them to deeply penetrate into all pores and sub-pores of the object's surface. This creates a lubricating film that provides a homogenous barrier between any moving parts.

Polarization: Next, the particles are polarized, meaning they develop a negative charge. Connecting to the object's positively charged surface ensures a unique adhesion to the surface. This is called a bonding bridge and offers higher resistance to high pressures and offering the lowest possible coefficient of friction, as low as 0.04.

Both of these attributes make the lubrication last generally up to 10 times longer than other lubricants and takes less overall to apply to a surface. MicPol® also repels water, thus preventing corrosion, refuses particle adhesion this avoiding the creation of abrasive pastes, which is typical with conventional oil-based lubricants. This level of protection is a massive advantage to industrial environments where humidity, dirt, and other contaminants are a factor.

HOW TO PURCHASE INTERFLON

To purchase Interflon products, please contact us at:

Sur-Seal will always beat Amazon's pricing by 10% and we have plenty in stock!

INTERFLON'S CORE PRODUCTS

Check out some of these videos about Interflon!

Demo of Interflon Paste HT1200 Rethreading

If you've ever had Stainless Steel Gall up on you while working with it and you don't know about Interflon's HT1200 anti-seize, please watch the following video. NOTHING ELSE like it.

From gear chains, to roller chains to conveyor chains, to forklift and even bicycle chains, every industrial or machine chain can use some Interflon onto it. Most of the Interflon products can be used in the food industry and they repel substances due to the MicPol technology prevalent in all Interflon products.

Cleaning or degreasing the chain? Use Metal Clean F.

Need an oil-based lubrication? Use Lube TF or Fin Super.

Lubricating conveyors in the food industry? Use Food Lube G150

See what a quick Interflon cleaning did to this AR-15.

Everybody has the same 1st time reaction.

With Interflon your Gun will handle extreme temperature swings and humid environments unlike any other CLP. Proven results.

Why use anything else?

Sur-Seal Inc Sponsored Dragster - 1000HP Test Runs

Using FIN SUPER on Bicycle Chains to Keep Them Clean

Interflon Crane Lubrication at DUFOUR

Interflon Bearing Lubrication

Interflon Chain Lubrication

Interflon for Cardboard Industry

Captain Chris Meyers FIN SUPER Review

FIN SUPER Demo at

West Marine

Additional Interflon Resources

TESTIMONIALS

From Retired NYC Law Enforcement Officer - Subject: Great Product!!

Hi Larry,

I just used the Lube TF on the cylinder of my Ruger SP101 that regular gun oil did not seem to have the correct lubricity that it needed. The firearm now works BETTER than when it came out of the factory. I will try this on my Glock at the next qualification next week and I am sure it will have the same results. I just left a message with Karen of my findings. Bravo! What a great product! My life depends on it. Can't wait to get more. Thanks.

From Michael Foster of SI Group, chemical plant in Rotterdam Junction, NY.

Larry,

Ok, I have permission to move forward with the MOC to get your products on our use list. I found the Metal Clean that you sent Doug.

I used it, it was awesome. Same goes for the HT1200. Amazing products.

After testing Fin Super, handgun manufacturer Beretta changed their Standard Operating Procedures of breaking down their guns at shooting competitions...from cleaning every 1,000 rounds to every 6,500 rounds... That was around 2009. It has been the same ever since.

Fleet Maintenance Mechanic at Water Treatment Plant

"We have an original untouched EGR valve on one of our 2000 Ford E-150 vans. I sprayed it overnight with TF and it came off like butter this morning. Unreal!"