Product Overview

Description:

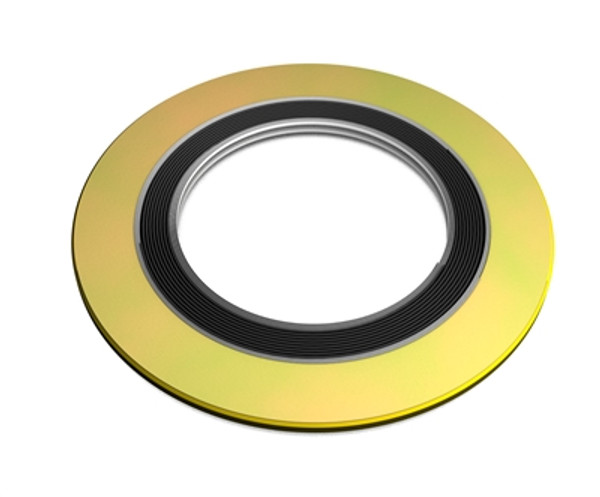

Spiral Wound Gaskets consist of several components: an outer centering ring, windings, a soft filler, and optionally, an inner guiding ring. The outer centering ring is a metallic guiding ring that accurately positions the gasket on the flange face, acting as a compression limiter and adds radial strength. The winding consists of a specified metallic strip material, tightly wound in conjunction with the soft filler material, resulting in excellent mechanical resistance, recovery and resilience. Depending on the metal and filler of the Spiral Wound gasket, they can be suited for temperatures ranging from cryogenic, freezing temperatures, to up to 2000 degrees Fahrenheit. Spiral Wound gaskets are known for their durability, easy installation and removal.

Ideal for uses within applications requiring higher pressure tolerance and tougher conditions, the purpose for the optional Inner Ring is to fill out the space between the flanges, protecting from erosion, corrosion and avoiding any turbulence in the flow of fluids.

The Inner Ring also prevents inner buckling of the sealing element, and creates a physical barrier that shields the sealing element from heat and the application's media.

Applications:

While often used within flanged joints and heat exchangers, Spiral Wound Gaskets are ideal in applications with high temperature variations, pressure variations, and/or flange rotation problems.

Typically Used Within:

1. Hydrocarbon and petrochemical processing and refining

2. Oil, Gas, Pulp and Paper Industries

3. Flanged Joints, Raised and Flat Face flanges

Specifications and Statistics

Pipe Size: 5" (5)

Inner Diameter: 6 1/8" (6.125)

Outer Diameter: 8 1/2" (7.75)

Sealing Outer Diameter: 7" (7)

Thickness: 1/8" (0.125)

Sealing Element Material: 316L Stainless Steel

Windings Material: 316 Stainless Steel with PTFE Filler

Max Pressure: 300#

Ring Band Color: Green

All Non-Inner Ring and Inner Ring Gaskets for standard flanges are 0.175 in (4.5mm) thick, fitted with 0.125 in (3.2mm) thick solid metal rings, unless otherwise stated.

Note: Max Pressure shows PSI rating for when flanges are at low temperatures, the higher the temperature, the lower the PSI rating