Image Gallery

Past Projects and Assisted Customers

This is the Back of Panel Pressure Gauges for CEMS monitoring system. We identified the gauges and provide with new.

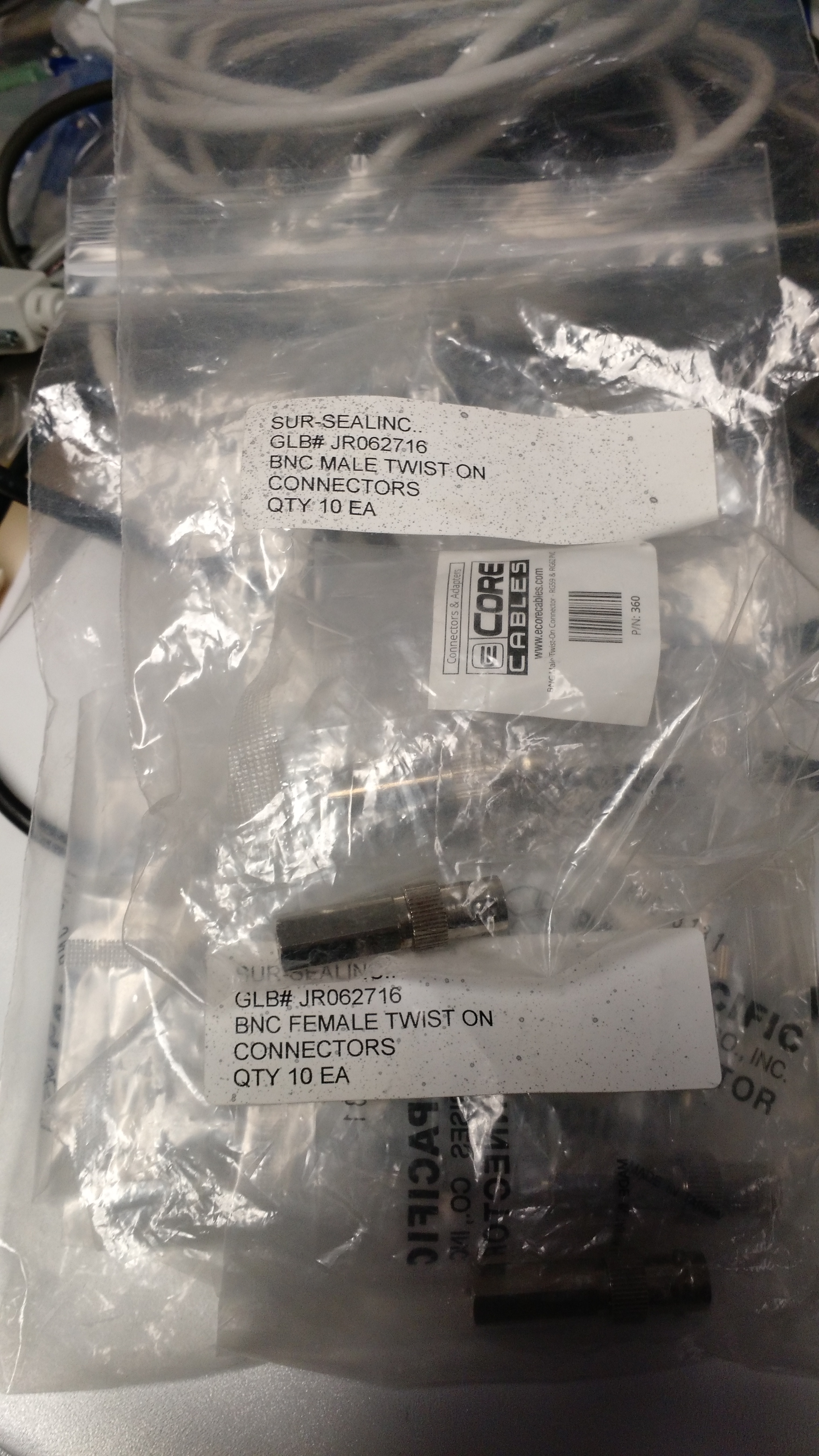

Provided these BNC Male and Female Twist on Connectors for Cogen Control Room

Cleaned and polished this Hastalloy Spool piece to 15RA inside and 25RA outside and this Filter Plate to 15RA both sides at a Pharma plant. We also provided them with new Hastalloy Filter plates per the sample.

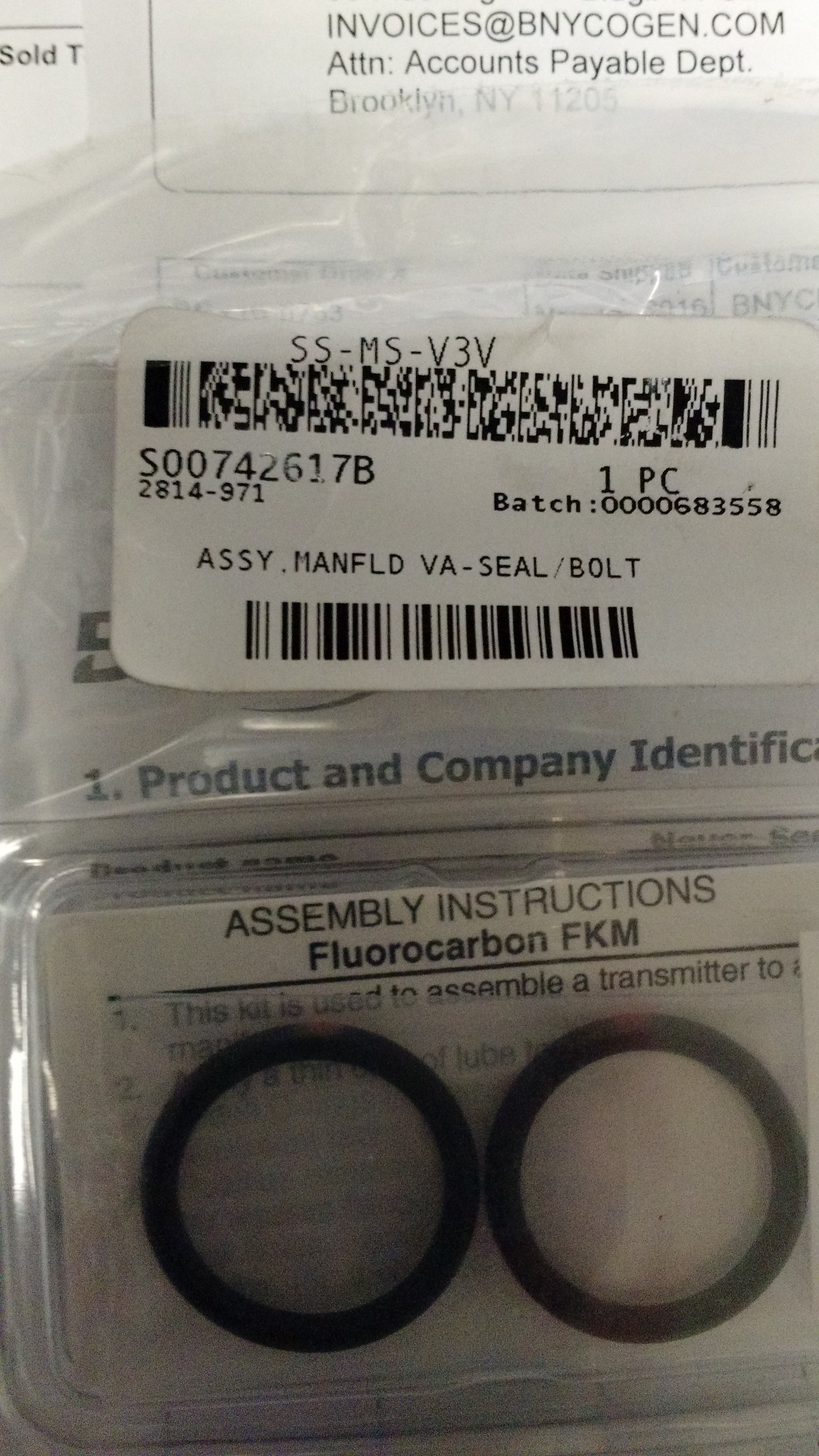

Confirmed material compatability and provided new Rosemount Flange adapter seals

Identified these threads and provided new fittings

Crossed these Filters over from an OEM at savings to Power plant with new Filters and also recondition the filters for the plant so they don't need new ones as often. Big savings overall.

Custom Specced in and fabricated this all Stainless Probe Tube assembly at a Pharma plant

Custom fabricated these Glass Filled teflon strike tools for PTFE flange for specific O-Ring install appllication

Custom fabricated these Glass Filled teflon strike tools for PTFE flange for specific O-Ring install appllication

Made sure to measure the Glass Filled teflon strike tools for PTFE flange for specific O-Ring install appllication.

Custom fabricated this prototype filter cloth cage for a Pharma plant (tape is on top to keep scratch free)

Worked with plant personel and engineers to custom make this Turbine Bearing spray shield for a Power Plant

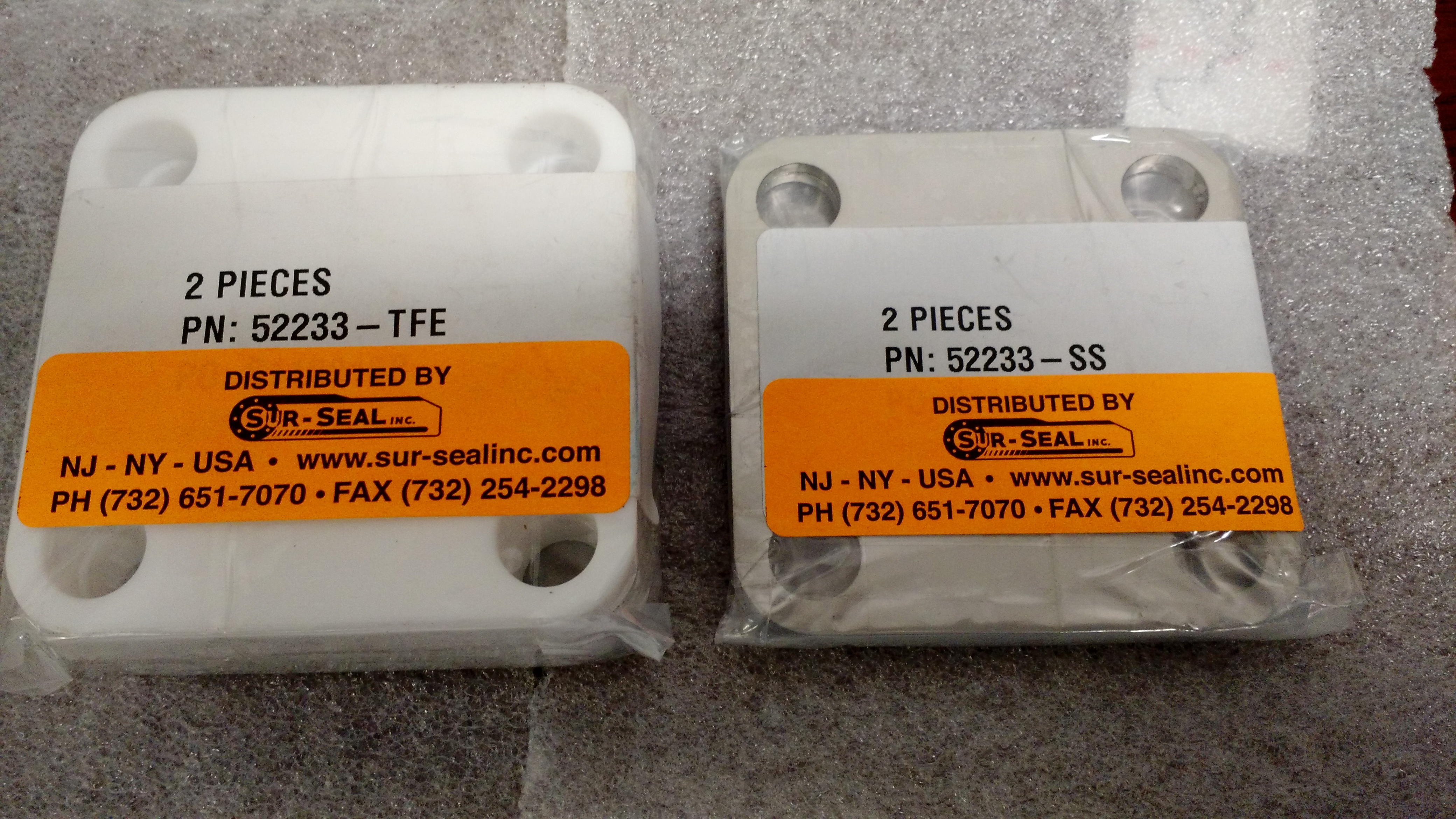

Custom made these PTFE Spacers and Stainless back up plates for a Pharmacuetical Plant

Procured, seasoned and prepared these short ribs for grill and eating application

Specced in and custom welded these BSPP x sanitary fittings for a Pharmacuetical Plant

Water Utility customer was using 1 regular worm drive on each side of this assembly and they were always leaking. We suggeseted to use to 2 of these T-Bolt Clamps on each side, and no problems since.

Power Plant customer had an OEM obsolete seal. We were able to cross over and provide them with an equivalent. Their OEM option was to send pumps back to OEM and get them retrofitted for new mechanical seal. Big savings with our solution.

Power Plant Customer needed ID & FD Fan bearings. We worked with the factory rep to id and provide. We had to scrape away years of paint to id properly. Got it all squared away and provided them the correct bearings.

Identified and provided this Dovetailed Grafoil Gasket

Specced in this FDA 20 Duro silicon gasket as part of a prototype for Pharmaceutical plant porject

Identified and provided this Flowswitch for CEMS monitoring system

This is a Fuel filter housing at a Power Plant. For years they always had leaks. They asked if we could help fix. We provided custom gaskets to serve as spacer to improve seal. No issues since.

Identified and provided inconel braided silica core rope

Identified and provided inconel braided silica core rope

Identified and provided inconel braided silica core rope

Identified and provided inconel braided silica core rope

Provided these Kalrez O-rings.

Worked with engineer and made custom welded Stainless Pipe assemblies for this Glove Isolation Box at a Pharmaceutical plant.

Provided new Swagelok Valve.

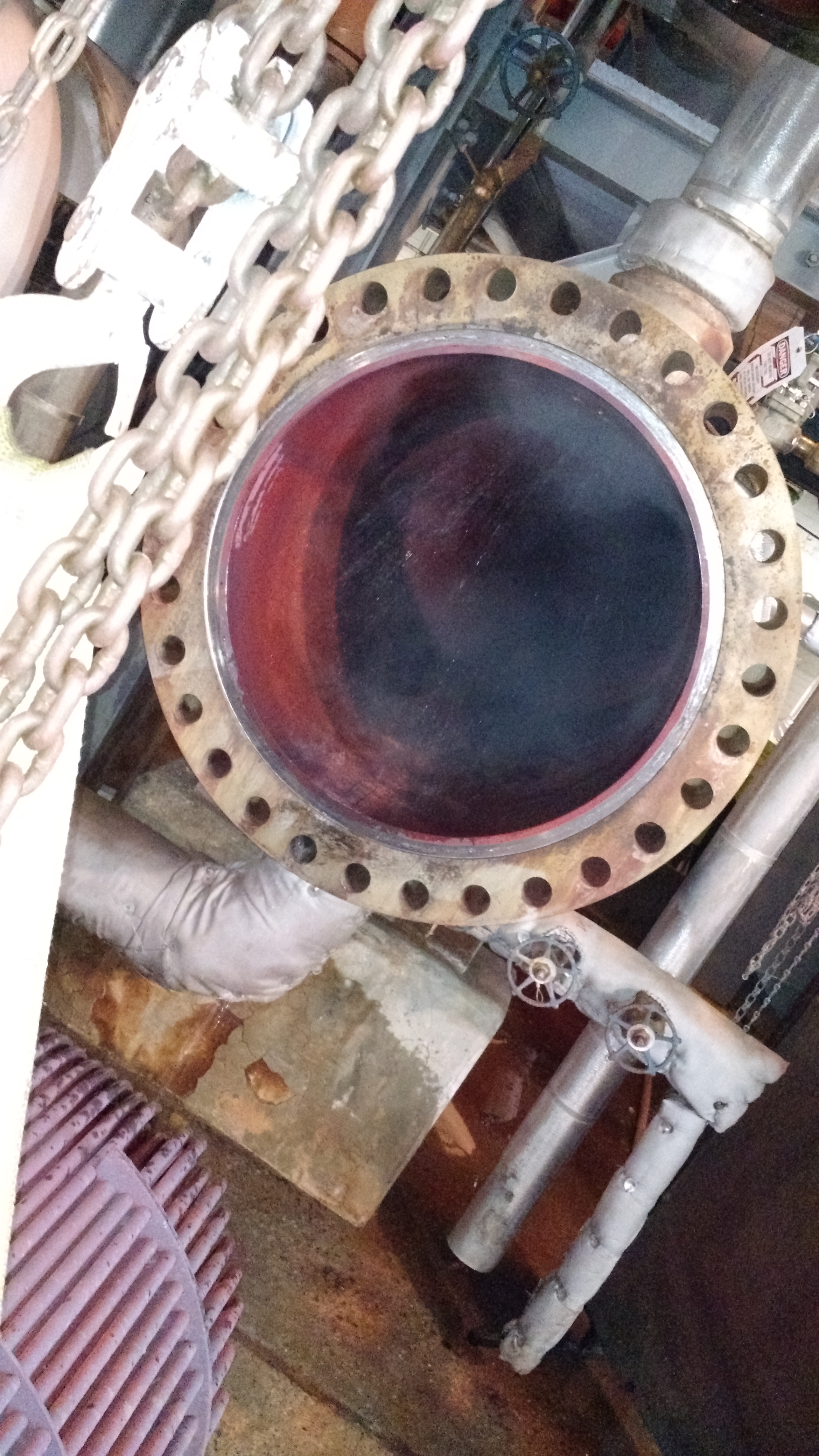

This is an open Flange at a Power Plant. We measured and provided new spiral wound gasket.Provided new Swagelok Valve.

Polished this Hastalloy Valve to 15RA inside and 25RA outside finish.

Improved the OEM design of this Isolation Glove Box "Port Blank".

Isolation Glove Box Port Blank PTFE prototype

Power plant customer had these grounding clamps and 1 aught wire. They needed a bunch of portable grounds assembled properly. We worked with them and used their materials, ordered the correct additional parts to assemble and provided them with completed (and certified) assemblies.

Provide Filters as part of quarterly and 6 week PM program at a Food plant.

Provide Filters as part of quarterly and 6 week PM program at a Food plant

Provided gauges and valves for CEMS monitoring system.

Power Plant had an obsolete actuator and used seal kit. We identified and replaced all seals for actuator.

Identified and replaced converters at a Power Plant.

Power plant customer had a Flood Barrier built for the plant. The contractor did not leave them extra replacement parts. We reverse engineered replacement custom Polypropylene Plugs and back up plates, custom aluminum Standoff Bolts and aluminum rod.

Identified and replaced Gas Turbine Fuel Pump Hose with exact same OEM hose at a Power plant.

Replaced Power Plant customer's heavy steel grates with much lighter fiberglass grates so plant personnel can move easier during routine PM.

Identified and replaced mechanicial seals and bearings in Water Pump at a Power Plant.

Identified and replaced shielded bearings for a pump at a Power Plant.

Identified and replaced single spring mechanical seal and shaft on this pump.